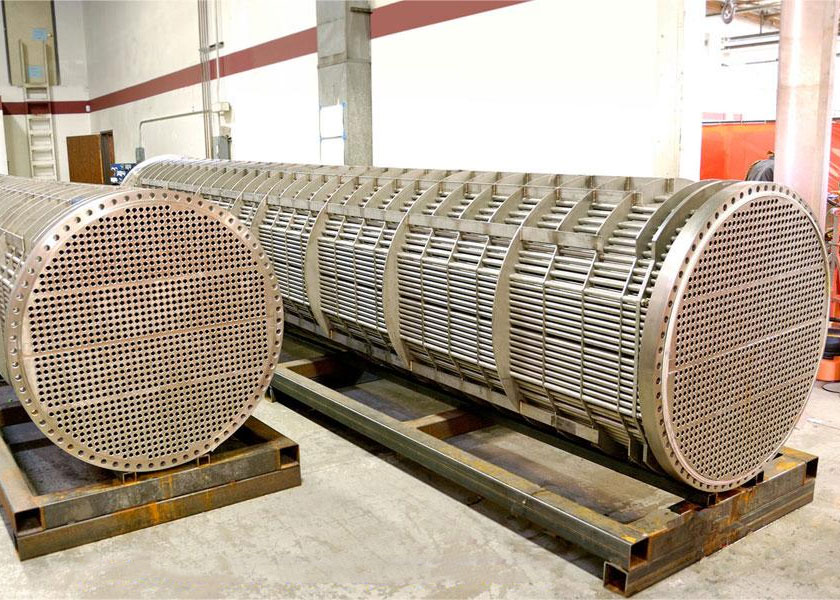

304 stainless steel heat exchanger

All about SS 304 Heat Exchanger Tubes

Since, Stainless Steel is the most versatile material available in the market that is used in manufacturing of various products. The presence of chromium in the steel enhances its resistive property and strength in extensive situations. The heat exchanger tubes made of SS304 exhibits good features as compared with other SS grades. The grade has excellent formability and welding characteristics which has made it dominant in manufacturing of stainless steel tubes. Grade 304 has excellent oxidation resistance, pitting resistance to chloride, crevice corrosion resistance, stress crack corrosion resistance and excellent strength at high temperature and pressure.

Beyond this, the grade exhibits excellent mechanical properties such as high tensile strength; greater short creep properties, good elongation, and improved yield strength are some of the traits found. Hence, due to all of these mentioned features in the grade has made it the most preferred choice for the industries to manufacture good quality Stainless Steel S30400 Heat Exchanger Tubes.

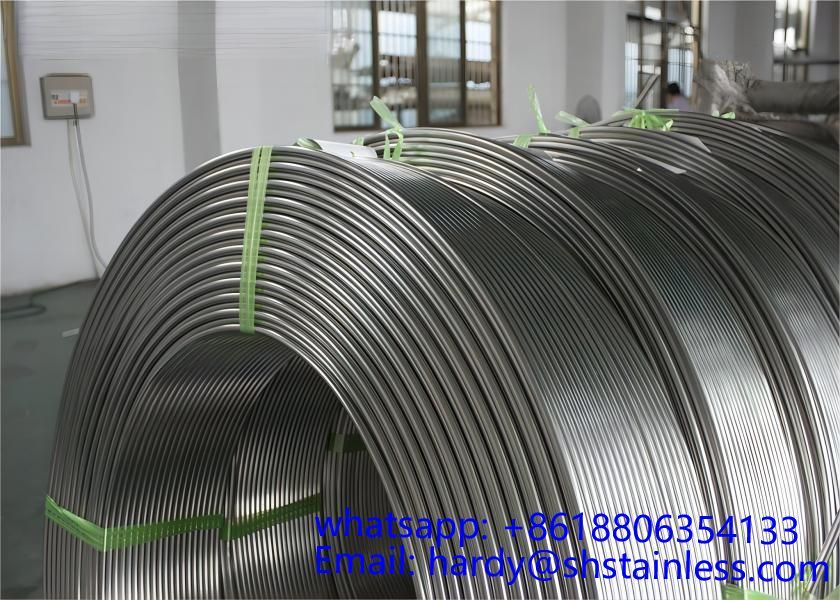

How are the exchangers tubes packed ?

The industry use efficient packaging methods in order to avoid any kind of quality issues. The SS grade heat exchanger tubes are packed in large wooden case, crates or pallets that are free from fumigation and other sort of impurities. Also, the tubes are handed to the buyers along with the relevant shipping documents.

Specifications

Equivalent Grade of Stainless Steel 304 Heat Exchanger Tubes

|

STANDARD |

UNS |

WERKSTOFF NR. |

JIS |

AFNOR |

BS |

GOST |

EN |

|

SS 304 |

S30400 |

1.4301 |

SUS 304 |

Z7CN18‐09 |

304S31 |

08Х18Н10 |

X5CrNi18-10 |

Chemical Composition of SS 304 Heat Exchanger Tube

|

SS |

304 |

|

Ni |

8 – 11 |

|

Fe |

Balance |

|

Cr |

18 – 20 |

|

C |

0.08 max |

|

Si |

0.75 max |

|

Mn |

2 max |

|

P |

0.040 max |

|

S |

0.030 max |

|

N |

– |

Mechanical Properties of SS 304 Heat Exchanger Tubes

| Grade |

304 |

| Tensile Strength (MPa) min |

515 |

| Yield Strength 0.2% Proof (MPa) min |

205 |

| Elongation (% in 50mm) min |

40 |

| Hardness |

– |

| Rockwell B (HR B) max |

92 |

| Brinell (HB) max |

201 |