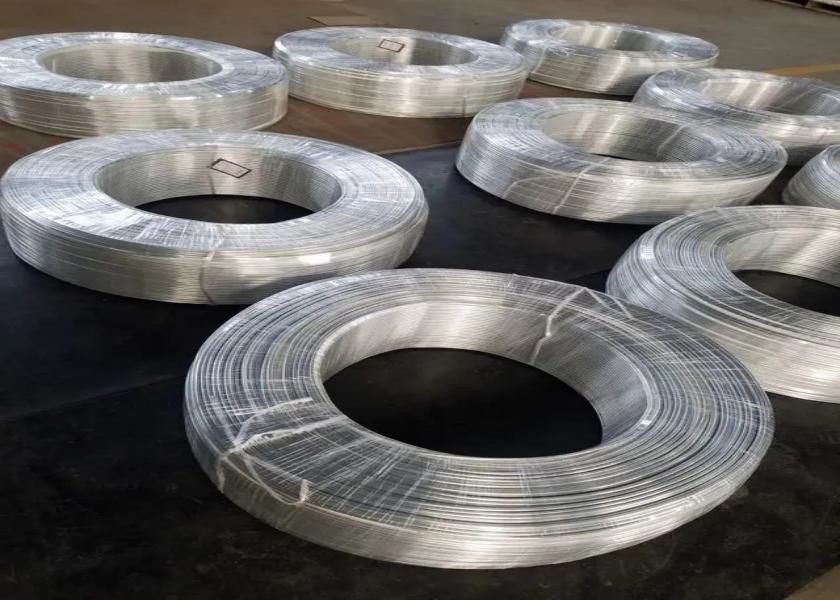

Stainless Steel Grade Super Duplex 2507 (UNS S32750) 6.35*0.7 mm coiled tube

ntroduction

Stainless Steel Grade Super Duplex 2507 (UNS S32750) 6.35*0.7 mm coiled tube

Stainless steel Super Duplex 2507 is designed to handle highly corrosive conditions and situations were high strength is required. High molybdenum, chromium and nitrogen content in Super Duplex 2507 help the material withstand pitting and crevice corrosion. The material is also resistant to chloride stress corrosion cracking, to erosion corrosion, to corrosion fatigue, to general corrosion in acids. This alloy has good weldability and very high mechanical strength.

The following sections will discuss in detail about stainless steel grade Super Duplex 2507.

Chemical Composition

Stainless Steel Grade Super Duplex 2507 (UNS S32750) 6.35*0.7 mm coiled tube

The chemical composition of stainless steel grade Super Duplex 2507 is outlined in the following table.

| Element | Content (%) |

|---|---|

| Chromium, Cr | 24 – 26 |

| Nickel, Ni | 6 – 8 |

| Molybdenum, Mo | 3 – 5 |

| Manganese, Mn | 1.20 max |

| Silicon, Si | 0.80 max |

| Copper, Cu | 0.50 max |

| Nitrogen, N | 0.24 – 0.32 |

| Phosphorous, P | 0.035 max |

| Carbon, C | 0.030 max |

| Sulfur, S | 0.020 max |

| Iron, Fe | Balance |

Physical Properties

Stainless Steel Grade Super Duplex 2507 (UNS S32750) 6.35*0.7 mm coiled tube

The physical properties of stainless steel grade Super Duplex 2507 are tabulated below.

| Properties | Metric | Imperial |

|---|---|---|

| Density | 7.8 g/cm3 | 0.281 lb/in3 |

| Melting point | 1350°C | 2460°F |

Applications

Super Duplex 2507 is widely used in the following sectors:

- Power

- Marine

- Chemical

- Pulp and paper

- Petrochemical

- Water desalinization

- Oil and gas production

Products made using Super Duplex 2507 include:

- Fans

- Wire

- Fittings

- Cargo tanks

- Water heaters

- Storage vessels

- Hydraulic piping

- Heat exchangers

- Hot water tanks

- Spiral wound gaskets

- Lifting and pulley equipment

- Propellers, rotors, and shafts