We use cookies to improve your experience. By continuing to browse this site, you agree to our use of cookies. Additional Information.

We use cookies to improve your experience. By continuing to browse this site, you agree to our use of cookies. Additional Information.

Additive manufacturing (AM) involves creating three-dimensional objects, one ultra-thin layer at a time, making it more expensive than traditional machining. However, only a small part of the powder deposited during the assembly process is soldered into the component. The rest then does not melt, so it can be reused. In contrast, if the object is created classically, material removal by milling and machining is usually required.

The characteristics of the powder determine the parameters of the machine and must be considered first. The cost of AM would be uneconomic given that the unmelted powder is contaminated and not recyclable. Damage to powders results in two phenomena: chemical modification of the product and changes in mechanical properties such as morphology and particle size distribution.

In the first case, the main task is to create solid structures containing pure alloys, so we need to avoid contamination of the powder, for example, with oxides or nitrides. In the latter case, these parameters are associated with fluidity and spreadability. Therefore, any change in the properties of the powder can lead to a non-uniform distribution of the product.

Data from recent publications indicate that classical flowmeters cannot provide adequate information on powder flowability in the production of powder bed additives. Regarding the characterization of raw materials (or powders), there are several appropriate measurement methods on the market that can satisfy this requirement. The stress state and the powder flow field must be the same in the measuring cell and in the process. The presence of compressive loads is incompatible with the free surface flow used in AM devices in shear cell testers and classical rheometers.

GranuTools has developed workflows for powder characterization in additive manufacturing. Our main goal was to have one tool per geometry for accurate process modeling, and this workflow was used to understand and track the evolution of powder quality over multiple print passes. Several standard aluminum alloys (AlSi10Mg) were selected for different durations at different thermal loads (from 100 to 200 °C).

Thermal degradation can be controlled by analyzing the ability of the powder to store a charge. The powders were analyzed for flowability (GranuDrum instrument), packing kinetics (GranuPack instrument) and electrostatic behavior (GranuCharge instrument). Cohesion and packing kinetics measurements are available for the following powder masses.

Powders that spread easily will experience a low cohesion index, while powders with fast filling dynamics will produce mechanical parts with less porosity compared to products that are harder to fill.

Three aluminum alloy powders (AlSi10Mg) stored in our laboratory for several months, with different particle size distributions, and one 316L stainless steel sample, referred to here as samples A, B and C, were selected. The characteristics of the samples may differ from others. manufacturers. Sample particle size distribution was measured by laser diffraction analysis/ISO 13320.

Since they control the parameters of the machine, the properties of the powder must be considered first, and if we consider the unmelted powder to be contaminated and unrecyclable, the cost of additive manufacturing will not be as economical as we would like. Therefore, three parameters will be investigated: powder flow, packing kinetics and electrostatics.

Spreadability is related to the uniformity and “smoothness” of the powder layer after the recoating operation. This is very important as smooth surfaces are easier to print and can be examined with the GranuDrum tool with adhesion index measurement.

Because pores are weak points in a material, they can lead to cracks. Packing dynamics is the second critical parameter because fast packing powders have low porosity. This behavior has been measured with GranuPack with a value of n1/2.

The presence of an electrical charge in the powder creates cohesive forces that lead to the formation of agglomerates. GranuCharge measures the ability of a powder to generate an electrostatic charge upon contact with a selected material during flow.

During processing, GranuCharge can predict flow deterioration, such as layer formation in AM. Thus, the obtained measurements are very sensitive to the state of the grain surface (oxidation, contamination and roughness). The aging of the recovered powder can then be accurately quantified (±0.5 nC).

The GranuDrum is based on the principle of a rotating drum and is a programmed method for measuring the flowability of a powder. A horizontal cylinder with transparent side walls contains half of the powder sample. The drum rotates around its axis at an angular speed of 2 to 60 rpm, and the CCD camera takes pictures (from 30 to 100 images at 1 second intervals). The air/powder interface is identified on each image using an edge detection algorithm.

Compute the average position of the interface and the oscillations around this average position. For each rotation speed, the flow angle (or “dynamic angle of repose”) αf is calculated from the mean interface position, and the dynamic adhesion index σf, which refers to interparticle bonding, is analyzed from interface fluctuations.

The flow angle is influenced by a number of parameters: friction between particles, shape and cohesion (van der Waals, electrostatic and capillary forces). Cohesive powders result in intermittent flow, while non-cohesive powders result in regular flow. Smaller values of the flow angle αf correspond to good flow properties. A dynamic adhesion index close to zero corresponds to a non-cohesive powder, therefore, as the adhesion of the powder increases, the adhesion index increases accordingly.

GranuDrum allows you to measure the angle of the first avalanche and aeration of the powder during the flow, as well as measure the adhesion index σf and the flow angle αf depending on the rotation speed.

GranuPack bulk density, tapping density and Hausner ratio measurements (also called “touch tests”) are very popular in powder characterization because of the ease and speed of measurement. The density of the powder and the ability to increase its density are important parameters during storage, transportation, agglomeration, etc. The recommended procedure is described in the Pharmacopoeia.

This simple test has three major drawbacks. The measurements are operator dependent and the filling method affects the initial powder volume. Visual measurements of volume can lead to serious errors in the results. Due to the simplicity of the experiment, we neglected the compaction dynamics between the initial and final dimensions.

The behavior of the powder fed into the continuous outlet was analyzed using automated equipment. Accurately measure the Hausner coefficient Hr, initial density ρ(0) and final density ρ(n) after n clicks.

The number of taps is usually fixed at n=500. The GranuPack is an automated and advanced tapping density measurement based on the latest dynamic research.

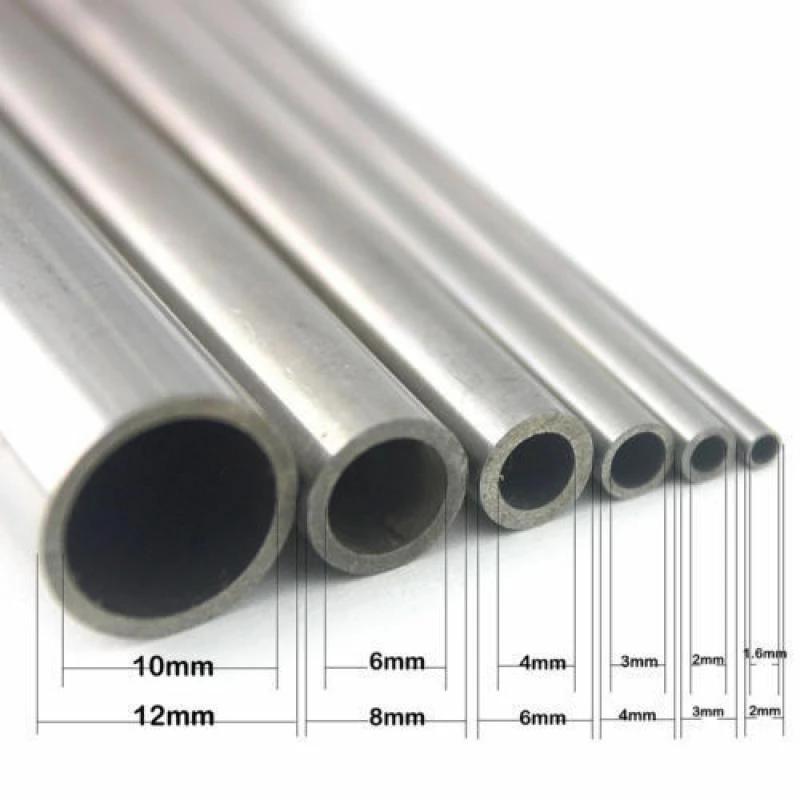

Other indexes can be used, but they are not listed here. The powder is placed in metal tubes and goes through a rigorous automatic initialization process. The extrapolation of the dynamic parameter n1/2 and the maximum density ρ(∞) is taken from the compaction curve.

A lightweight hollow cylinder sits on top of the powder bed to keep the powder/air interface level during compaction. The tube containing the powder sample rises to a fixed height ∆Z and then falls freely to a height, usually fixed at ∆Z = 1 mm or ∆Z = 3 mm, measured automatically after each impact. By height, you can calculate the volume V of the pile.

Density is the ratio of the mass m to the volume V of the powder layer. The powder mass m is known, the density ρ is applied after each release.

The Hausner coefficient Hr is related to the compaction rate and is analyzed by the equation Hr = ρ(500) / ρ(0), where ρ(0) is the initial bulk density and ρ(500) is the calculated tap density after 500 taps. Results are reproducible with a small amount of powder (usually 35 ml) using the GranuPack method.

The properties of the powder and the nature of the material from which the device is made are key parameters. During the flow, electrostatic charges are generated inside the powder, and these charges are caused by the triboelectric effect, the exchange of charges when two solids come into contact.

When the powder flows inside the device, triboelectric effects occur at the contact between the particles and at the contact between the particle and the device.

Upon contact with the selected material, the GranuCharge automatically measures the amount of electrostatic charge generated inside the powder during flow. A sample of the powder flows in a vibrating V-tube and falls into a Faraday cup connected to an electrometer that measures the charge the powder acquires as it moves through the V-tube. For reproducible results, feed the V-tube frequently with a rotating or vibrating device.

The triboelectric effect causes one object to gain electrons on its surface and thus be negatively charged, while another object loses electrons and is therefore positively charged. Some materials gain electrons more easily than others, and similarly, other materials lose electrons more easily.

Which material becomes negative and which becomes positive depends on the relative tendency of the materials involved to gain or lose electrons. To represent these trends, the triboelectric series shown in Table 1 was developed. Materials that tend to be positively charged and others that tend to be negatively charged are listed, while materials that do not exhibit behavioral tendencies are listed in the middle of the table.

On the other hand, this table only provides information on the trend of material charge behavior, so GranuCharge was created to provide accurate values for powder charge behavior.

Several experiments were carried out to analyze thermal decomposition. The samples were left at 200°C for one to two hours. The powder is then immediately analyzed with GranuDrum (thermal name). The powder is then placed in a container until it reaches ambient temperature and then analyzed using GranuDrum, GranuPack and GranuCharge (i.e. “cold”).

Raw samples were analyzed using GranuPack, GranuDrum and GranuCharge at the same humidity/room temperature, i.e. relative humidity 35.0 ± 1.5% and temperature 21.0 ± 1.0 °C.

The cohesion index calculates the flowability of a powder and correlates with changes in the position of the interface (powder/air), which reflect only three contact forces (van der Waals, capillary and electrostatic). Before the experiment, record the relative humidity (RH, %) and temperature (°C). Then pour the powder into the drum container and start the experiment.

We concluded that these products were not sensitive to caking when considering thixotropic parameters. Interestingly, thermal stress changed the rheological behavior of the powders of samples A and B from shear thickening to shear thinning. On the other hand, Samples C and SS 316L were not affected by temperature and showed only shear thickening. Each powder showed better spreadability (ie lower cohesion index) after heating and cooling.

The temperature effect also depends on the specific surface area of the particles. The greater the thermal conductivity of the material, the greater the effect on temperature (i.e. ???225°?=250?.?-1.?-1) and ?316? 225°?=19?.?-1.?-1), the smaller the particles, the more important the effect of temperature. Working at elevated temperatures is a good choice for aluminum alloy powders due to their increased spreadability, and cooled samples achieve even better flowability compared to pristine powders.

For each GranuPack experiment, the weight of the powder was recorded before each experiment, and the sample was subjected to 500 impacts with an impact frequency of 1 Hz with a free fall of the measuring cell of 1 mm (impact energy ∝). Samples are dispensed into the measuring cells according to software instructions independent of the user. The measurements were then repeated twice to assess reproducibility and to examine the mean and standard deviation.

After the GranuPack analysis is completed, initial packing density (ρ(0)), final packing density (on several clicks, n = 500, i.e. ρ(500)), Hausner ratio/Carr index (Hr/Cr) , and two recorded parameters (n1/2 and τ) related to compaction dynamics. The optimal density ρ(∞) is also shown (see Appendix 1). The table below reorganizes the experimental data.

Figures 6 and 7 show the overall compaction curves (bulk density versus number of impacts) and the n1/2/Hausner parameter ratio. Error bars calculated using averages are shown on each curve, and standard deviations were calculated from repeatability tests.

The 316L stainless steel product was the heaviest product (ρ(0) = 4.554 g/mL). In terms of tapping density, SS 316L is still the heaviest powder (ρ(n) = 5.044 g/mL), followed by Sample A (ρ(n) = 1.668 g/mL), followed by Sample B (ρ (n) = 1.668 g/ml) (n) = 1.645 g/ml). Sample C was the lowest (ρ(n) = 1.581 g/mL). According to the bulk density of the initial powder, we see that sample A is the lightest, and taking into account the error (1.380 g / ml), samples B and C have approximately the same value.

When the powder is heated, its Hausner ratio decreases, which occurs only for samples B, C and SS 316L. For Sample A, this cannot be done due to the size of the error bars. For n1/2, the parameter trends are more difficult to identify. For sample A and SS 316L, the value of n1/2 decreased after 2 h at 200°C, while for powders B and C it increased after thermal loading.

A vibrating feeder was used for each GranuCharge experiment (see Figure 8). Use 316L stainless steel pipe. Measurements were repeated 3 times to assess reproducibility. The weight of the product used for each measurement was approximately 40 ml and no powder was recovered after measurement.

Before the experiment, the weight of the powder (m.p., g), relative air humidity (RH, %), and temperature (°C) are recorded. At the start of the test, measure the charge density of the primary powder (q0 in µC/kg) by introducing the powder into the Faraday cup. Finally, record the mass of the powder and calculate the final charge density (qf, µC/kg) and Δq (Δq = qf – q0) at the end of the experiment.

The raw GranuCharge data are shown in Table 2 and Figure 9 (σ is the standard deviation calculated from the results of the reproducibility test), and the results are presented as histograms (only q0 and Δq are shown). The SS 316L had the lowest initial cost; this may be due to the fact that this product has the highest PSD. Regarding the initial charge amount of the primary aluminum alloy powder, no conclusions can be drawn due to the size of the errors.

After contact with 316L stainless steel pipe, sample A acquired the least amount of charge compared to powders B and C, which highlights a similar trend, when SS 316L powder is rubbed with SS 316L, a charge density close to 0 is found (see triboelectric series). Product B is still more charged than A. For sample C, the trend continues (positive initial charge and final charge after leakage), but the number of charges increases after thermal degradation.

After 2 hours of thermal stress at 200 °C, the behavior of the powder becomes spectacular. In samples A and B, the initial charge decreases and the final charge changes from negative to positive. SS 316L powder had the highest initial charge and its charge density change became positive but remained low (ie 0.033 nC/g).

We investigated the effect of thermal degradation on the combined behavior of aluminum alloy (AlSi10Mg) and 316L stainless steel powders while analyzing the original powders in ambient air after 2 hours at 200°C.

The use of powders at high temperature can improve the spreadability of the product, and this effect seems to be more important for powders with high specific surface area and materials with high thermal conductivity. GranuDrum was used to evaluate flow, GranuPack was used for dynamic filling analysis, and GranuCharge was used to analyze the triboelectricity of the powder in contact with 316L stainless steel tubing.

These results were established using GranuPack, which shows the improvement in the Hausner coefficient for each powder (with the exception of sample A due to size error) after the thermal stress process. Looking at the packing parameters (n1/2), there were no clear trends as some products showed an increase in packing speed while others had a contrasting effect (eg Samples B and C).

Post time: Jan-10-2023