|

Description |

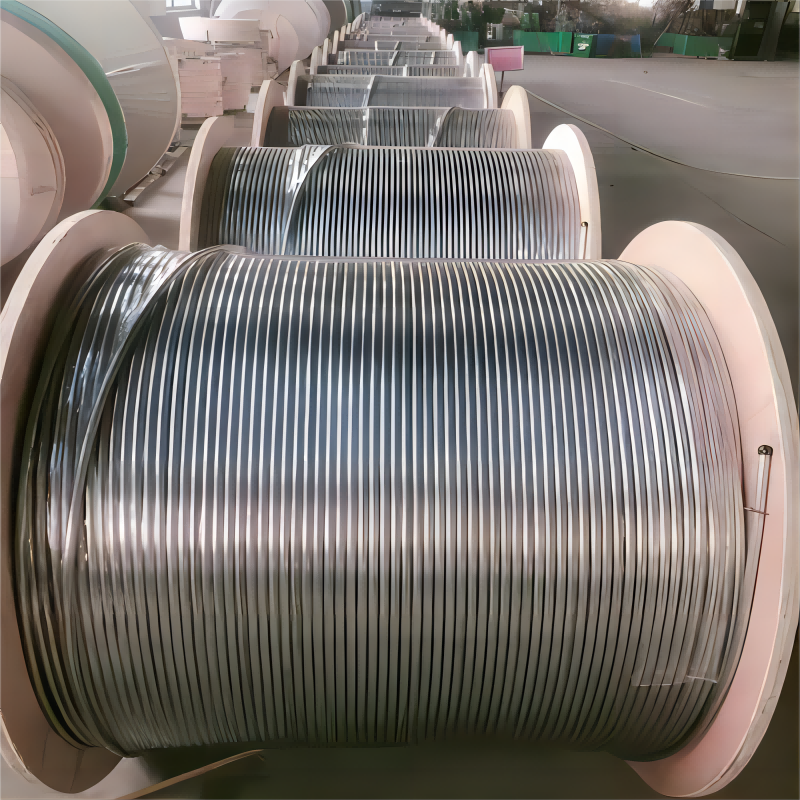

Seamless Stainless Steel Coil Tubing |

||

|

Material&Standard&Size |

Material: 201,202,301,304,304L,310S,316,316L,321,347 Standard:ASTM (ASME) SA / A312 /A213 /A269 ,DIN,JIS,EN |

||

| Out Diameter:Φ6mm-25mmWall Thickness:Φ0.7mm-2.11mm

Tolerance:OD:±0.08mm, WT:±10% |

|||

|

Length |

According to different sizes,the one coil length is within 500 meter the whole coil tube is not welded point |

||

|

Surface Treatment |

Pickling Or Polish Annealed |

||

|

Technical |

Cold rolling firstly,then cold drawn coil |

||

|

Delivery Type |

Soft |

||

|

Type |

Seamless and Welde |

||

|

Application |

Stainless steel coil tubing is widely used in Oil Drilling,Chemical,SteamShip Manufacturing Industry,Heat Exchang and Cooling Condenser Chemical Industry,Gas Pipeline etc |

||

Stainless Steel Grade

| Chemical Composition | MaterialComposition | 201 | 304L | 304 | 316 | 316L |

| C | ≤0.15 | ≤0.03 | ≤0.08 | ≤0.08 | ≤0.03 | |

| Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

| Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤2.00 | |

| P | ≤0.06 | ≤0.035 | ≤0.035 | ≤0.035 | ≤0.035 | |

| S | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 | |

| Cr | 16-18 | 18-20 | 18-20 | 16-18 | 16-18 | |

| Ni | 3.5-5.5 | 8-12 | 8-10.5 | 10-14 | 10-14 | |

| Mo | 2.0-3.0 | 2.0-3.0 | ||||

| Mechanical Property | Material Item | 201 | 304L | 304 | 316 | |

| Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | ||

| Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | ||

| Extension | ≥30% | ≥40% | ≥35% | ≥35% | ||

| Hardness (HV) | <253 | <200 | <200 | <200 | ||

Post time: Jan-20-2023