Alloy 625 Stainless Steel Coil Tubing Price

Chemical Composition, %

Alloy 625 material is non-magnetic, austenitic, and displays high tensile strength, fabricability, and brazeability. Due to its high nickel content, this alloy is nearly immune to chloride ion stress-corrosion cracking and pitting, which is commonly found in metals in seawater applications like heat exchangers, fasteners, and cable sheathing.

| Cr | Ni | Mo | Co + Nb | Ta | Al | Ti | C |

| 20.00-30.00 | Remainder | 8.0-10.0 | 1.0 max | 3.15-4.15 | .40 max | .40 max | .10 max |

| Fe | Mn | Si | P | S |

| 5.0 max | .50 max | .50 max | .015 max | .015 max |

In what applications is Inconel 625 used?

- Inconel 625 is mainly used in Aerospace industry

- Aircraft ducting systems

- Jet engine exhaust systems

- Engine thrust-reverser systems

- Specialized seawater equipment

- Chemical process equipment

ASTM Specifications

| Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet/Plate | Bar | Forging | Fitting | Wire |

| B444 | B705 | B444 | B704 | B443 | B446 | - | - | - |

Mechanical Properties

| Temp° F | Tensile (psi) | .2% Yield (psi) | Elongation in 2 “ (%) |

| 70 | 144,000 | 84,000 | 44 |

| 400 | 134,000 | 66,000 | 45 |

| 600 | 132,000 | 63,000 | 42.5 |

| 800 | 131,500 | 61,000 | 45 |

| 1000 | 130,000 | 60,500 | 48 |

| 1200 | 119,000 | 60,000 | 34 |

| 1400 | 78,000 | 58,500 | 59 |

| 1600 | 40,000 | 39,000 | 117 |

Inconel 625 Melting Point

| Melting Point |

1290 - 1350 °C |

2350 - 2460 °F |

Inconel 625 Equivalent

|

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

|

Inconel 625 |

2.4856 |

N06625 |

NCF 625 |

NA 21 |

ХН75МБТЮ |

NC22DNB4MNiCr22Mo9Nb |

NiCr23Fe |

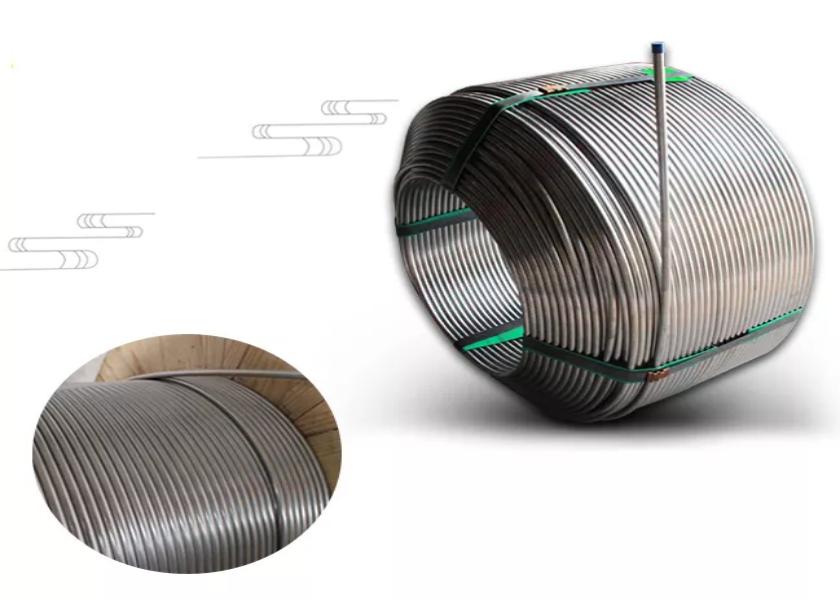

Alloy 625 Tubing

Alloy 625 is an austenitic nickel-chromium-molybdenum superalloy known for being resistant to crevice corrosion and oxidation at elevated temperatures. These temperatures can range from cryogenic to extremely hot levels of 1,800°F. The behavior and chemical composition of this grade make it well suited for nuclear and aerospace applications. Also, with the addition of niobium, alloy 625 tubing finds itself with increased strength sans heat treating. This property makes the grade an excellent option for fabrication.

Product Specifications

ASTM B444 / ASME SB444 / NACE MR0175

Size Range

| Outside Diameter (OD) | Wall Thickness |

| .375"–.750" | .035”–.095” |

Chemical Requirements

Alloy 625 (UNS N06625)

Composition %

| C Carbon |

Mn Manganese |

Si Silicon |

P Phosphorous |

Cr

Chromium |

Nb+Ta Niobium-Tantalum |

Co Cobalt |

Mo Molybdenum |

Fe Iron |

Al Aluminum |

Ti Titanium |

Ni Nickel |

| 0.10 max | 0.50 max | 0.50 max | 0.015 max | 20.0–23.0 | 3.15–4.15 | 1.0 max | 8.0–10.0 | 5.0 max | 0.40 max | 0.40 max | 58.0 min |

Dimensional Tolerances

| OD | OD Tolerance | Wall Tolerance |

| .375”–0.500” excl | +.004”/-.000” | ± 10% |

| 0.500”–1.250” excl | +.005”/-.000” | ± 10% |

Mechanical Properties

| Yield Strength: | 60 ksi min |

| Tensile Strength: | 120 ksi min |

| Elongation (min 2"): | 30% |

Factoy Photos

Inspection

Shipping & Packing

Test Report