3003 aluminum coiled tube

What Does 3003 Mean In Aluminum Coil?

The numbers in the aluminum coil are the alloy code, which tells you what elements are in the alloy. The first number refers to its most significant alloying element. The second number indicates the alloy’s variation (if different from zero), and the third and fourth number identifies its series.

For the 3003 aluminum coil, the first digit ‘3’ means it is an alloy in the manganese series, the ‘0’ means it has no variation, and the last numbers ‘03’ means it is from the 3000 series. This numbering scheme is based on the International Alloy Designation System.

Properties Of 3003 Alloy Aluminum Coil

3003 aluminum coil has a chemical composition limit of 0.6 silicon, 0.7 iron, 0.05-0.20 copper, 1-1.5 manganese, 0.10 zinc, and 0.15 from other elements.

3003 aluminum has a tensile strength of up to 200MPa, and all methods can readily weld it. It is resistant to corrosion in most environments except when exposed to seawater or other corrosive atmospheres containing chlorine or fluorine.

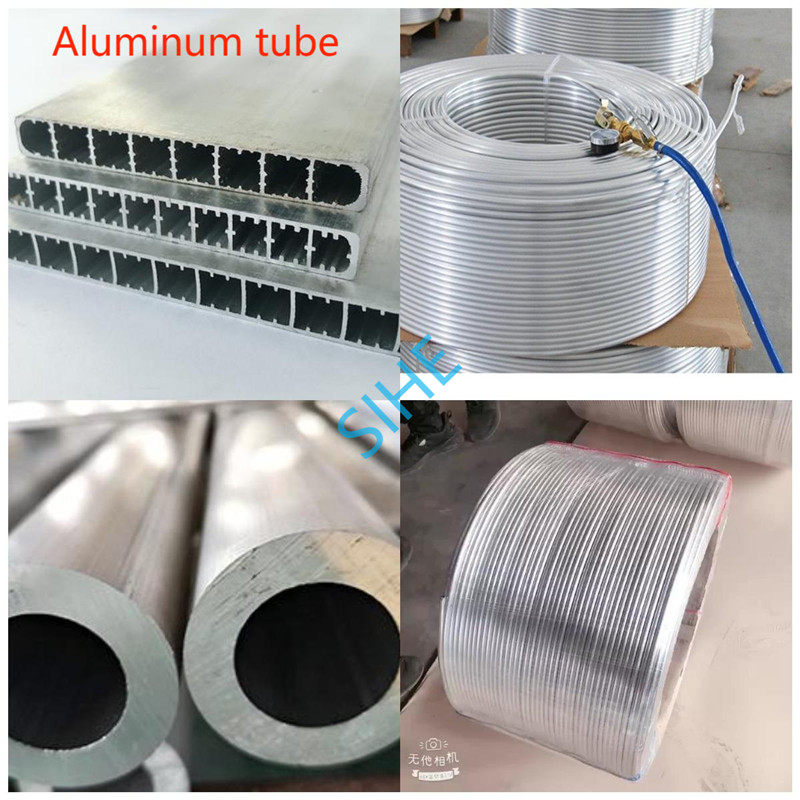

3003 alloy aluminum coils come in various shapes and sizes—ranging from sheets just 0.4 mm thick to 12 mm thick tubes. There are plenty of options when deciding on materials for each project. They’re also available in coils (for industrial use) and straight lengths (for commercial projects).

3003 Aluminum Coil Vs. 3004 Aluminum Coil

3003 aluminum coil and 3004 aluminum coil are both used in a wide range of applications. While they are similar, they are not identical, and each has its benefits and drawbacks.

The 3003 and 3004 alloys are similar in composition, but 3004 has an additional 1% magnesium, making it slightly stronger. This results in better corrosion resistance when exposed to acid environments, making this alloy more expensive to produce than the 3003 alloys.

The 3003 aluminum alloy offers better ductility than the 3004 alloy and weldability due to its lower magnesium content; however, it has a lower strength-to-weight ratio than the latter material because of its lower density.

Concerning environmental application, 3003 can be heat treated and cold worked, but 3004 can only be cold worked.

Specifications

| Alloy No. |

Temper | Straight Tube | LWC | ||

| O.D(mm) | W T(mm) | O.D(mm) | W T | ||

| 1060(L2) | R(H112) | 6~30 | 0.6~3 | 4~22 | 0.2~2 |

| M(O) | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| H 14 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| 3A21 3003 3103 (LF21) |

M(O) | 6~30 | 0.6~3 | 4~22 | 0.2~2 |

| H12 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| H14 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| H18 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| 6063 (LD31) |

M(O) | 6~30 | 0.6~3 | 4~22 | 0.5~2 |

| T4 | 6~30 | 0.6~3 | 4~22 | 0.5~2 | |

| T6 | 6~30 | 0.6~3 | 4~22 | 0.5~2 | |

Specification of Inner Groove Aluminum Tube(Size can be customized)

| Specification(mm) | Wall thickness(mm) | Grooved Height(mm) | Helical Angle(°) |

| 7 | 0.4-0.5 | 0.05-0.18 | 18 |

| 7.94 | 0.4-0.5 | 0.05-0.18 | 18 |

| 9.52 | 0.45-0.55 | 0.05-0.18 | 18 |

Mechanical Properties of Inner Aluminum Grooved Tube

| Material | Tensile | Elongation Rate | Expanding Rate |

| 3003 | 130MPA | 35 | 40 |

Specification of Package Coil

| O.D | 6.35 | 7.94 | 9.52 | 12.7 | 15.88 | 19.05 |

| Wall Thickness | 0.7-1.0 | 0.8-1,2 | 0.8-1.2 | 1-1.5 | 1-1.5 | 1-1.5 |

Quanlity Gurantee

| A1050 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Others |

| 99.5~100 | 0~0.25 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.40 | 0~0.03 |

| A1060 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Others |

| 99.6-100 | 0~0.25 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.03 | 0~0.03 | / | 0~0.35 | |

| A1070 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Others |

| 99.7~100 | 0~0.2 | 0~0.04 | 0~0.03 | 0~0.04 | 0~0.03 | 0~0.03 | 0~0.05 | 0~0.25 | |

| A3003 Aluminium Chemical Composition | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Others Single | |

| others | 0~0.6 | 0.05~0.20 | 0~0.1 | 1.0~1.5 | 0~0.70 | 0~0.05 | |

| Alloy | Temper | Specification | |||

| Thickness(mm) | Diameter(mm) | Tensile strength | Hardness | ||

| 7075 7005(tube) | T5,T6,T9 | >0.5 | 5.0-80 | >310 Mpa | >140 |

| 6061 6063(profiles) | T5,T6 | >1.6 | 10-180 | >572 Mpa | HB90-110 |

| Length: < 6Meter | |||||

| TEMPER | THICKNESS(mm) | TENSILE STRENGTH | ELONGATION% | Standard |

| T5 | 0.4-5 | 60-100 | ≥ 20 | GB/T3190-1996 |

| T6 | 0.5-6 | 70-120 | ≥ 4 | |

| T9 | 0.5-6 | 85-120 | ≥ 2 |

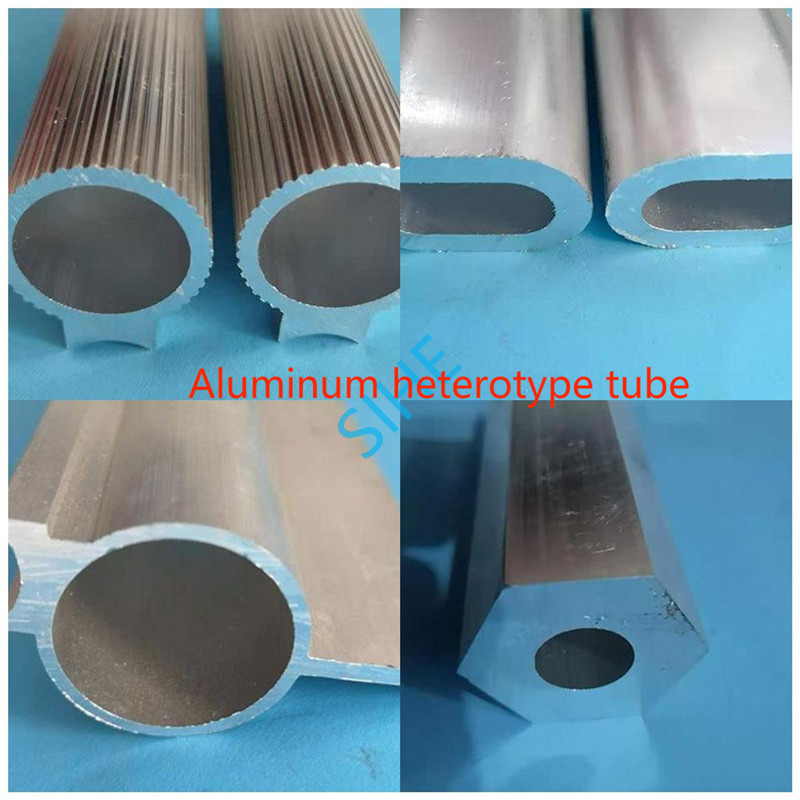

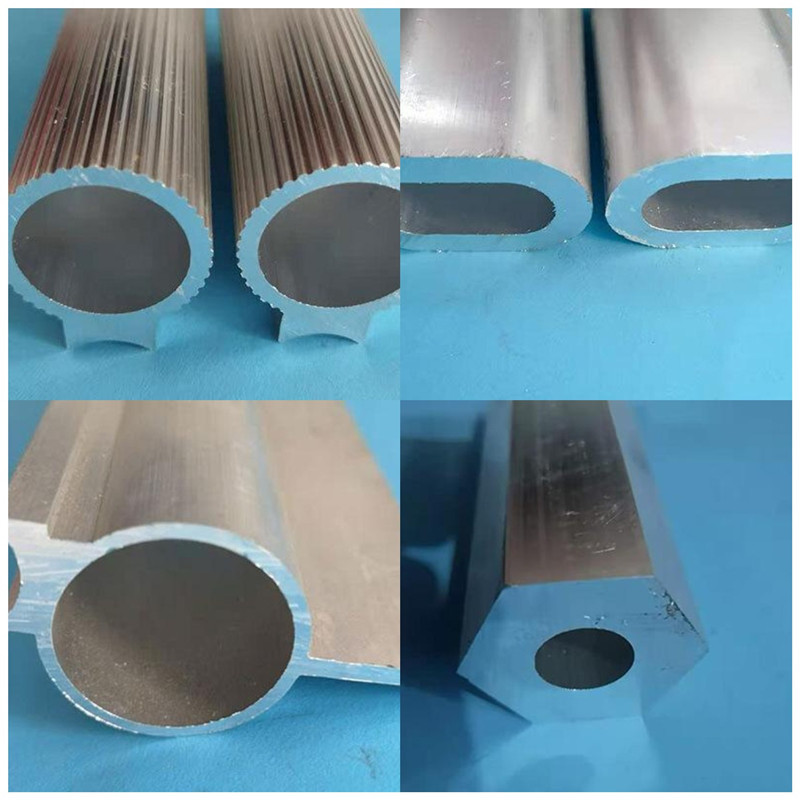

Aluminum product