2507 Stainless Steel Coil Tubing Price

Duplex Stainless Steel Composition

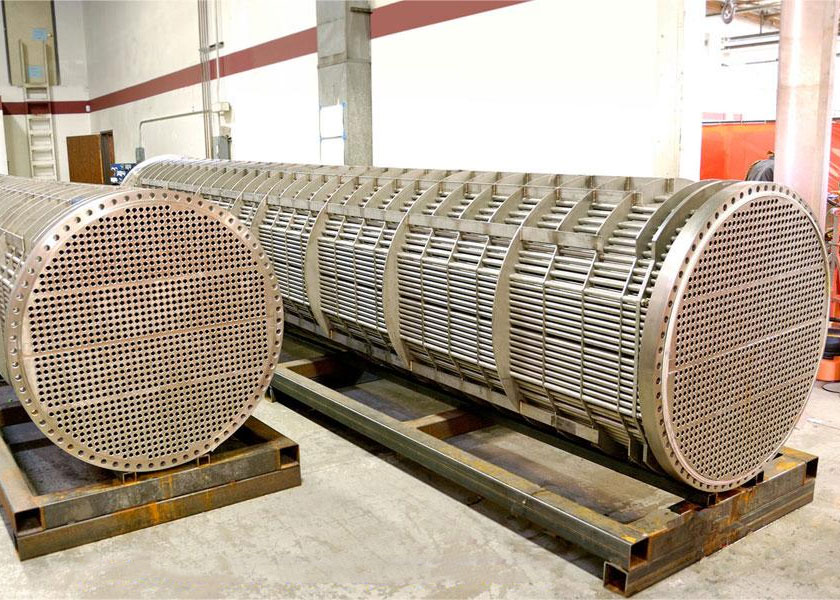

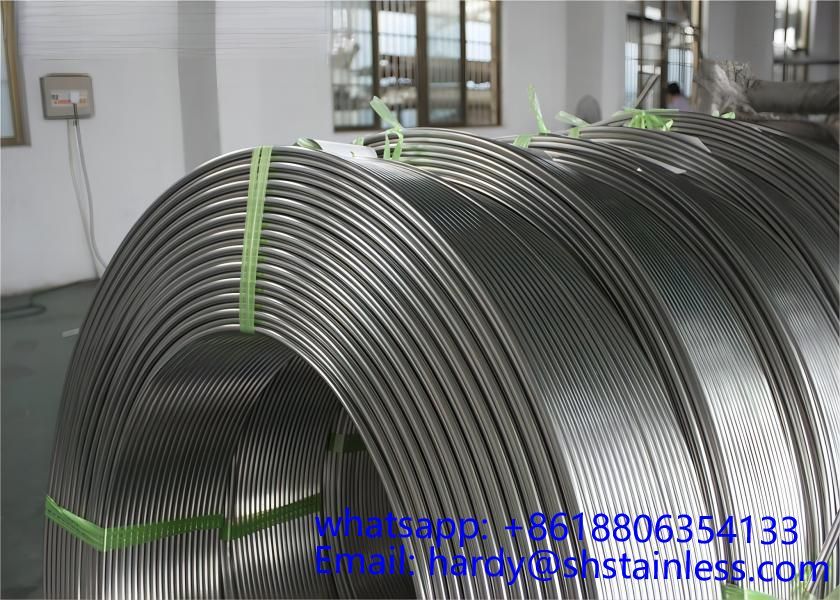

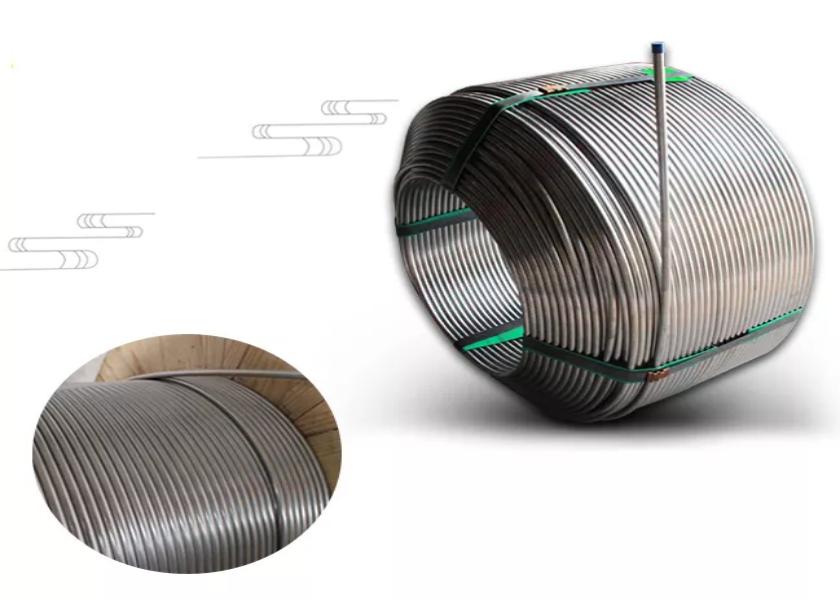

Super Duplex 2507 is available in various forms such as Straight, Coiled, Seamless, Seam welded, cold redrawn and annealed. It’s typical applications are in Subsea control lines, Offshore, Fire-fighting systems, Injection & ballast water systems, Heat exchangers etc. where industries predominantly using this Grade are Chemical processing industry and petroleum industry.

S32750 / S32760 Super Duplex Chemical Composition

|

S32750 / S32760 |

C |

N |

P |

Si |

Mn |

Mo |

Ni |

Cr |

S |

Other |

|

0.030 |

0.24/0.32 |

0.035 |

0.80 |

1.20 |

3.0/5.0 |

6.00/8.00 |

24.0/26.0 |

0.020 |

Cu:0.50 |

Super Duplex Steel S32750 / S32760 Mechanical Properties

|

S32750 / S32760 |

Density |

Melting Point |

Yield Strength (0.2%Offset) |

Tensile Strength |

Elongation |

|

7.8 g/cm3 |

1350 °C (2460 °F) |

Psi – 80000 , MPa – 550 |

Psi – 116000 , MPa – 800 |

15 % |

Super Duplex 2507 Equivalent

Equivalent Grades for S32750 / S32760 Super Duplex Stainless Steel

|

Super Duplex 2507 Standard Specification |

UNS |

WERKSTOFF NR. |

|

Super Duplex S32750 |

S32750 |

1.4410 |

|

Super Duplex S32760 |

S32760 |

1.4410 |

Super Duplex 2507 (UNS S32750)

Composition %

| C Carbon |

Mn Manganese |

P Phosphorous |

S Sulfur |

Si Silicon |

Ni Nickel |

Cr Chromium |

Mo Molybdenum |

N Nitrogen |

Cu Copper |

| 0.030 max | 1.20 max | 0.035 max | 0.020 max | 0.80 max | 6.0–8.0 | 24.0–26.0 | 3.0–5.0 | 0.24–0.32 | 0.50 max |

Dimensional Tolerances

| OD | OD Tolerance | Wall Tolerance |

| ≤ .500” | ± .005” | ± 15% |

| 0.500”–1.500” excl | ± .005” | ± 10% |

Mechanical Properties

| Yield Strength: | 80 ksi min |

| Tensile Strength | 116 ksi min |

| Elongation (min 2”) | 15% |

| Hardness (Rockwell C Scale) | 32 HRC max |

Industry Applications

Chemical Process

Super Duplex 2507 is designed for demanding applications which require exceptional strength and corrosion resistance, which are found in chemical process, petrochemical, and seawater equipment. The alloy is used in salt evaporation processes, heat exchangers, and hydrochloric acid environments.

Factoy Photos

Inspection

Shipping & Packing

Test Report