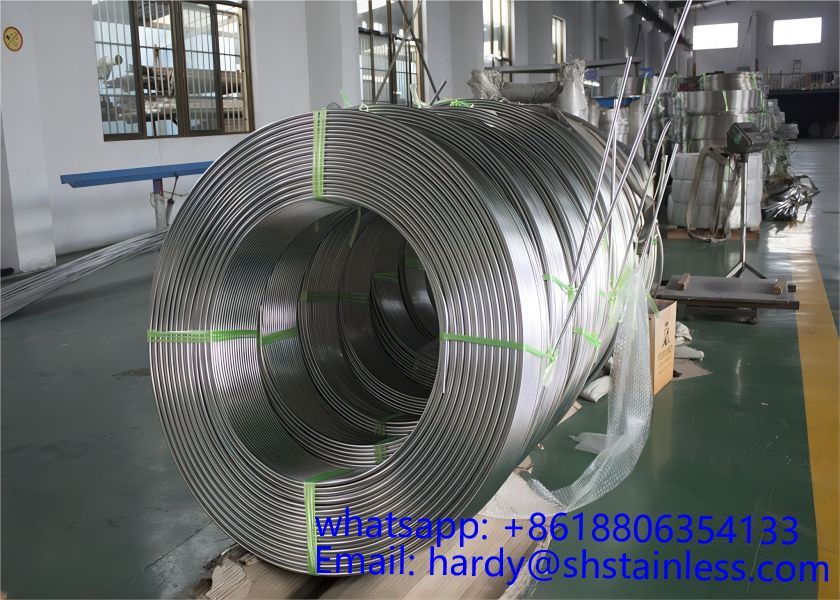

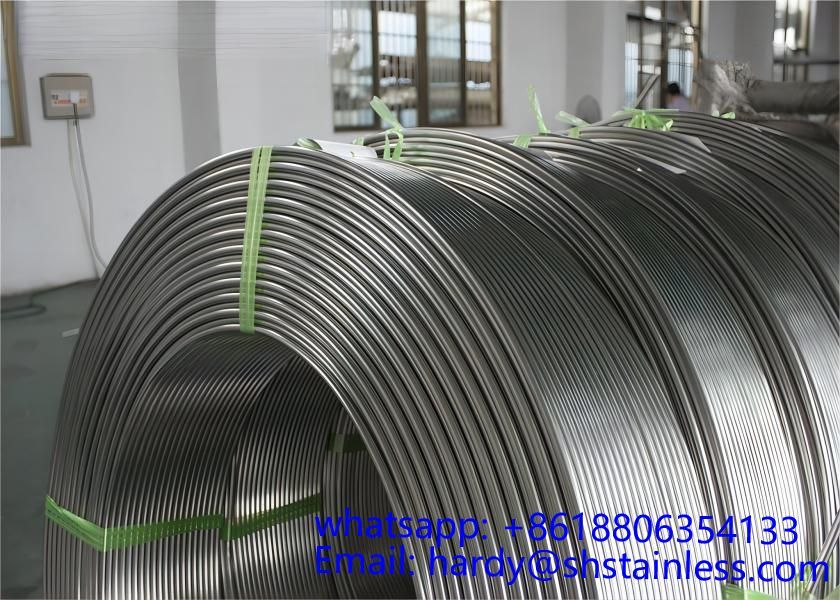

2205 stainless steel 6.35*0.52mm coiled tubing

PROCESSING – COLD FORMING

2205 stainless steel 6.35*0.52mm coiled tubing

Duplex 2205 has shown good formability in a variety of fabrications. The high strength of Duplex 2205 can pose problems. Even when the equipment has sufficient power, allowance must be made for higher spring-back caused by the grade’s high strength.

MACHINABILITY

2205 stainless steel 6.35*0.52mm coiled tubing

Duplex 2205 is somewhat more difficult to machine than the 300 series austenitic stainless steels. Higher cutting forces are required and more rapid tool wear is typical. Some guidelines for machining are: A) Use powerful, rigid machines with extremely strong rigid mounting of tools and work piece, B) Minimize vibration by keeping the tool extension as short as possible, C) Use a nose radius on the tool, no longer than necessary, for carbides that have a sharp edge while still providing adequate strength, D) Design machining sequences to always provide for a depth of cut below the work hardened layer resulting from the previous passes.

2205 stainless steel 6.35*0.52mm coiled tubing

Chemical Properties

| C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 2205(S31803) | 0.03 max | 2.0 max | 1.0 max | 0.03 max | 0.02 max | min: 21.0max: 23.0 | min: 2.5max: 3.5 | min: 4.5max: 6.5 | min: 0.08max: 0.20 |

| 2205(S32205) | 0.03 max | 2.0 max | 1.0 max | 0.03 max | 0.02 max | min: 22.0max: 3.5 | min: 3.0max: 3.5 | min: 4.5max: 6.5 | min: 0.14max: 0.20 |

Mechanical Properties

| Grade | Tensile Strength ksi (min) | Yield Strength 0.2% ksi (min) | Elongation % | Hardnes (HB) MAX |

| 2205 | 90 | 65 | 25 | 217 |

Physical Properties

| Density lbm/in3 | Electrical Resistivity mW•in | Thermal Conductivity (BTU/hr•ft•°F) | Heat Capacity BTU/lbm•°F | Electrical Resistivity (in x 10-6) | |

| at 68°F | 0.278 | 27.6 | 8.7 | 0.112 | 33.5 |

| at 212°F | 26.1 | 9.2 | 0.119 | 35.4 | |

| at 392°F | 25.4 | 9.8 | 0.127 | 37.4 | |

| at 572°F | 24.9 | 10.4 | 0.134 | 39.4 |