1070 aluminum coiled tube

Heat treatment process for 1070

oil quenching and tempering. The strength of this kind of steel wire is not as good as that of lead bath treated steel wire, but the properties are uniform and the cost is low. After cold roll forming, the stress is removed. Pull to the specified size, and then anneal. The mechanical properties of the softened coil can be obtained only after quenching and tempering at medium temperature.

Characteristics and Applications for 1070

It has the characteristics of high plasticity, corrosion resistance, good conductivity and thermal conductivity, but low strength, not strengthened by heat treatment, poor machinability, and can accept contact welding and gas welding. Make more use of its advantages to manufacture some structural parts with specific performance, such as aluminum foil made gasket and capacitor, electron tube isolation net, wire, cable protective cover, net, wire core and aircraft ventilation system parts and decorative parts.

Specifications

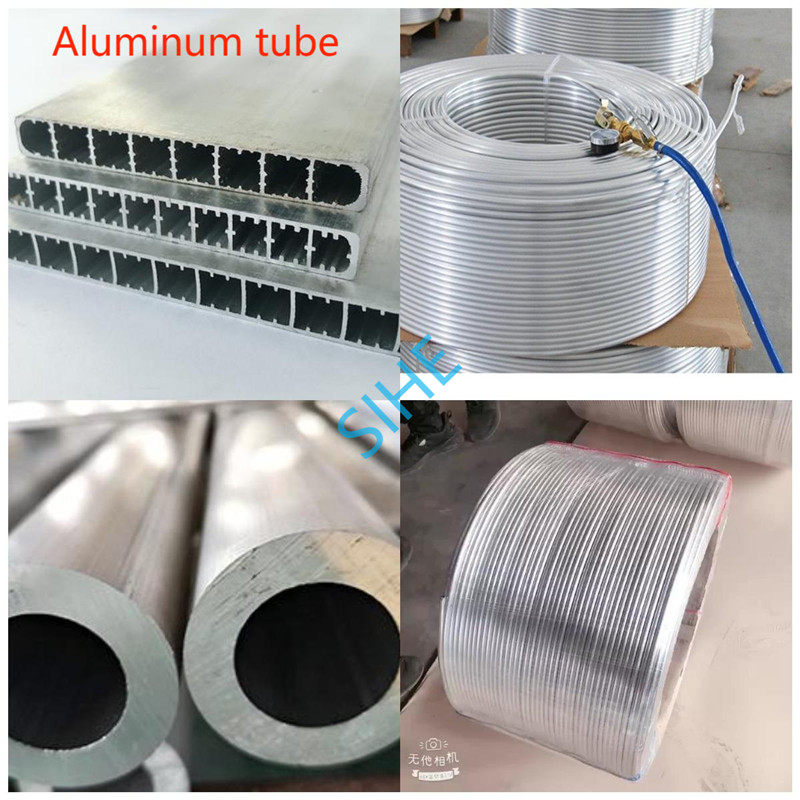

Typical Specification of Aluminum tube

| Alloy No. |

Temper | Straight Tube | LWC | ||

| O.D(mm) | W T(mm) | O.D(mm) | W T | ||

| 1060(L2) | R(H112) | 6~30 | 0.6~3 | 4~22 | 0.2~2 |

| M(O) | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| H 14 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| 3A21 3003 3103 (LF21) |

M(O) | 6~30 | 0.6~3 | 4~22 | 0.2~2 |

| H12 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| H14 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| H18 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| 6063 (LD31) |

M(O) | 6~30 | 0.6~3 | 4~22 | 0.5~2 |

| T4 | 6~30 | 0.6~3 | 4~22 | 0.5~2 | |

| T6 | 6~30 | 0.6~3 | 4~22 | 0.5~2 | |

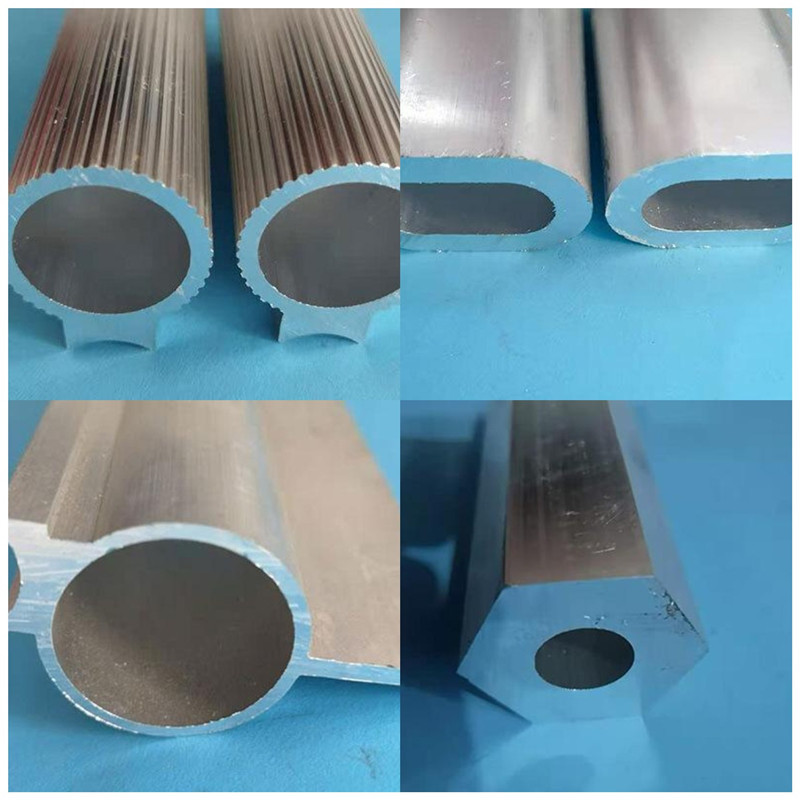

Specification of Inner Groove Aluminum Tube(Size can be customized)

| Specification(mm) | Wall thickness(mm) | Grooved Height(mm) | Helical Angle(°) |

| 7 | 0.4-0.5 | 0.05-0.18 | 18 |

| 7.94 | 0.4-0.5 | 0.05-0.18 | 18 |

| 9.52 | 0.45-0.55 | 0.05-0.18 | 18 |

Mechanical Properties of Inner Aluminum Grooved Tube

| Material | Tensile | Elongation Rate | Expanding Rate |

| 3003 | 130MPA | 35 | 40 |

Specification of Package Coil

| O.D | 6.35 | 7.94 | 9.52 | 12.7 | 15.88 | 19.05 |

| Wall Thickness | 0.7-1.0 | 0.8-1,2 | 0.8-1.2 | 1-1.5 | 1-1.5 | 1-1.5 |

quanlity gurantee

1) surface appearance: flat clean surface no whole, scratch, oil dirty or oxidation.

2) cutting edge: neat cutting edge no burrs.

3)Quality goal: the frist product inspection qualified rate is 98%. Customer satisfaction by 95%. Material: A1050, A1060, A1070, A3003, and so on

| A1050 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Others |

| 99.5~100 | 0~0.25 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.40 | 0~0.03 |

| A1060 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Others |

| 99.6-100 | 0~0.25 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.03 | 0~0.03 | / | 0~0.35 | |

| A1070 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Others |

| 99.7~100 | 0~0.2 | 0~0.04 | 0~0.03 | 0~0.04 | 0~0.03 | 0~0.03 | 0~0.05 | 0~0.25 | |

| A3003 Aluminium Chemical Composition | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Others Single | |

| others | 0~0.6 | 0.05~0.20 | 0~0.1 | 1.0~1.5 | 0~0.70 | 0~0.05 | |

| Alloy | Temper | Specification | |||

| Thickness(mm) | Diameter(mm) | Tensile strength | Hardness | ||

| 7075 7005(tube) | T5,T6,T9 | >0.5 | 5.0-80 | >310 Mpa | >140 |

| 6061 6063(profiles) | T5,T6 | >1.6 | 10-180 | >572 Mpa | HB90-110 |

| Length: < 6Meter | |||||

| TEMPER | THICKNESS(mm) | TENSILE STRENGTH | ELONGATION% | Standard |

| T5 | 0.4-5 | 60-100 | ≥ 20 | GB/T3190-1996 |

| T6 | 0.5-6 | 70-120 | ≥ 4 | |

| T9 | 0.5-6 | 85-120 | ≥ 2 |

Aluminum product