1060 aluminum coiled tube

ASTM B210 1060 Aluminium coil tube for Evaporator

1060 aluminum alloy is an aluminum-based alloy in the "commercially pure" wrought family (1000 or 1xxx series). It is fundamentally very similar to 1050 aluminum alloy, with the difference coming down to 0.1% aluminum by weight.

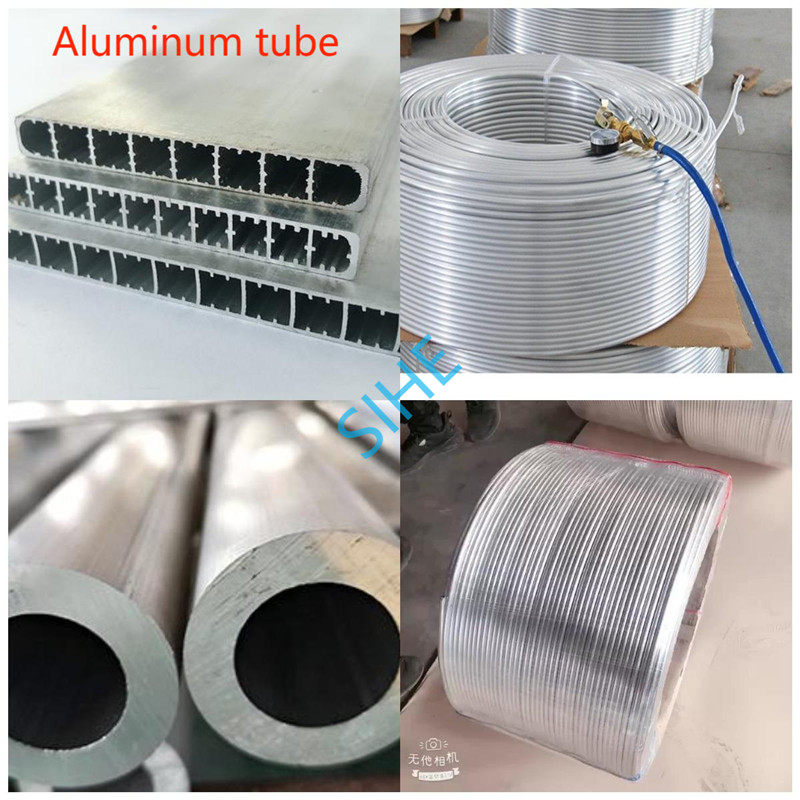

Aluminum tube for the HVAC&R industry. the surface of the coiled tube is smooth, no pores, no wear, and nitrogen is maintained. aluminum tubes are especially suited to long production runs for industrial applications. Mainly be used on the air-conditioner, freezer, refrigeration, Condenser, intercooler, evaporator, warm wind movement, air conditioner pipeline, car radiator, etc.

1 . Alloy: ASTM B241 1050/1060/1070

2. Temper: O/H12/H14/H16/H22/H24/H26/H112/F

3. Thickness: 0.7mm--1.5mm

4. Diameter: according to customer’s requirements

5. Tolerance: +/- 0.05mm

6. Application: air conditioner, refrigerator, roll-bond evaporator, heat exchanger, oven gas, condenser, and intercooler and so on.

7. Package: Wooden pallets or boxes suitable for long-distance sea transportation, it is can be customized by clients.

Specifications

|

A1050 Aluminium Chemical Composition |

|||||||||

|

Al |

Si |

Cu |

Mg |

Zn |

Mn |

Ti |

V |

Fe |

Others |

|

99.5~100 |

0~0.25 |

0~0.05 |

0~0.05 |

0~0.05 |

0~0.05 |

0~0.03 |

0~0.05 |

0~0.40 |

0~0.03 |

|

A1060 Aluminium Chemical Composition |

|||||||||

|

Al |

Si |

Cu |

Mg |

Zn |

Mn |

Ti |

V |

Fe |

Others |

|

99.6-100 |

0~0.25 |

0~0.05 |

0~0.03 |

0~0.05 |

0~0.03 |

0~0.03 |

/ |

0~0.35 |

|

|

A1070 Aluminium Chemical Composition |

|||||||||

|

Al |

Si |

Cu |

Mg |

Zn |

Mn |

Ti |

V |

Fe |

Others |

|

99.7~100 |

0~0.2 |

0~0.04 |

0~0.03 |

0~0.04 |

0~0.03 |

0~0.03 |

0~0.05 |

0~0.25 |

|

|

Physical Property of 1050 1060 1070 aluminum tube pipe |

||||||

|

Alloy |

Temper |

Wall thickness |

Room temperature Test Result |

|||

|

Tension Strength/MPa |

Yield Strength/MPa |

Elongation/% |

||||

|

A50mm |

A |

|||||

|

Not less than |

||||||

|

1050 |

O,H111 |

All |

60 ~ 100 |

20 |

25 |

23 |

|

H112 |

All |

60 |

20 |

25 |

23 |

|

|

F |

All |

- |

- |

- |

- |

|

|

1060 |

O |

All |

60 ~ 95 |

15 |

25 |

22 |

|

H112 |

All |

60 |

- |

25 |

22 |

|

|

1070 |

O |

All |

60 ~ 95 |

- |

25 |

22 |

|

H112 |

All |

60 |

20 |

25 |

22 |

|

quanlity gurantee

1) surface appearance: flat clean surface no whole, scratch, oil dirty or oxidation.

2) cutting edge: neat cutting edge no burrs.

3)Quality goal: the frist product inspection qualified rate is 98%.customer satisfaction by 95%.Material: A1050, A1060, A1070, A3003, and so on

| A1050 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Others |

| 99.5~100 | 0~0.25 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.40 | 0~0.03 |

| A1060 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Others |

| 99.6-100 | 0~0.25 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.03 | 0~0.03 | / | 0~0.35 | |

| A1070 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Others |

| 99.7~100 | 0~0.2 | 0~0.04 | 0~0.03 | 0~0.04 | 0~0.03 | 0~0.03 | 0~0.05 | 0~0.25 | |

| A3003 Aluminium Chemical Composition | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Others Single | |

| others | 0~0.6 | 0.05~0.20 | 0~0.1 | 1.0~1.5 | 0~0.70 | 0~0.05 | |

| Alloy | Temper | Specification | |||

| Thickness(mm) | Diameter(mm) | Tensile strength | Hardness | ||

| 7075 7005(tube) | T5,T6,T9 | >0.5 | 5.0-80 | >310 Mpa | >140 |

| 6061 6063(profiles) | T5,T6 | >1.6 | 10-180 | >572 Mpa | HB90-110 |

| Length: < 6Meter | |||||

| TEMPER | THICKNESS(mm) | TENSILE STRENGTH | ELONGATION% | Standard |

| T5 | 0.4-5 | 60-100 | ≥ 20 | GB/T3190-1996 |

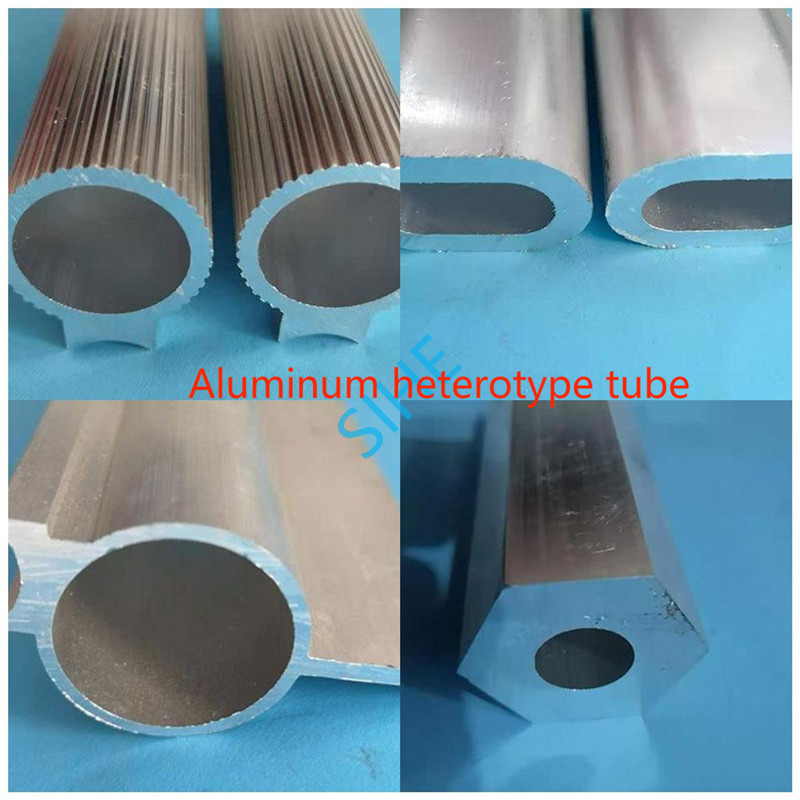

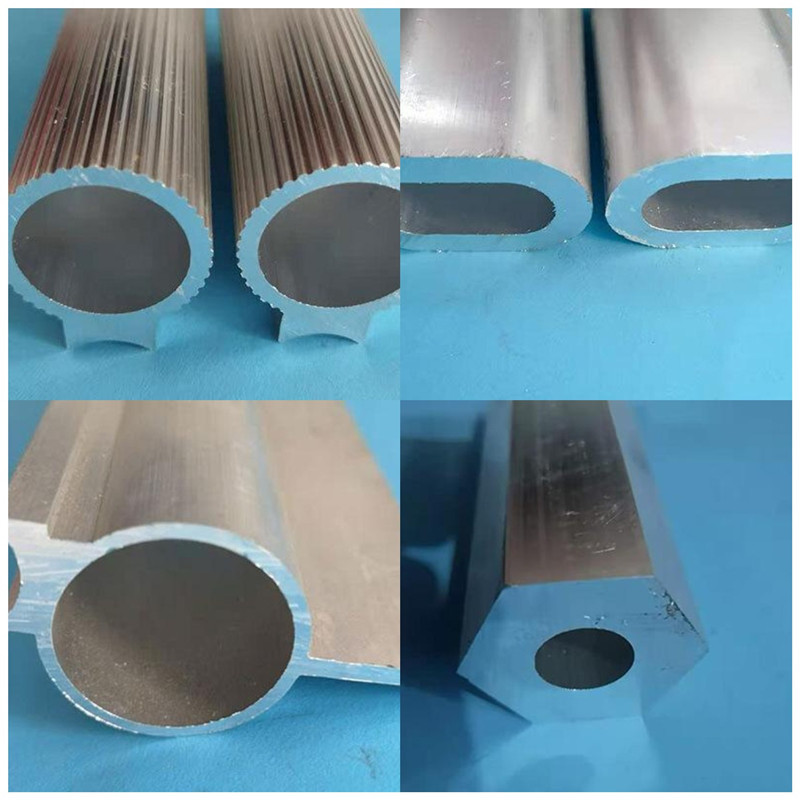

Aluminum product